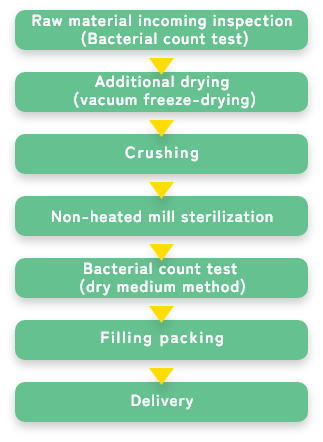

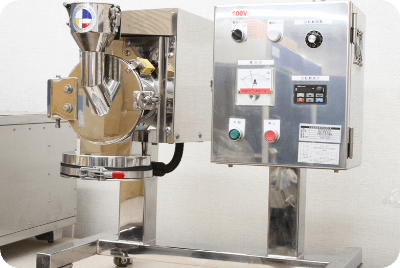

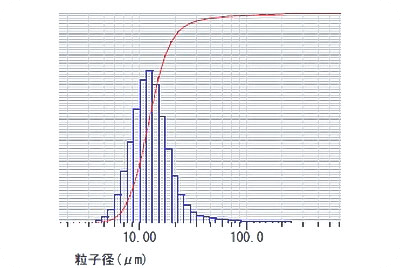

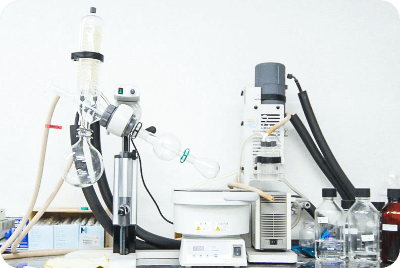

05Non-heated mill sterilization

Compared to the normal sterilization method, in the case of non-heated mill sterilization, the deterioration of nutritional components is small, and it is possible to sterilize while maintaining the color and aroma of various powder raw materials.

For the heat-resistant bacteria, spore-forming bacteria, water-soluble extract powder, etc. that could not be sterilized by conventional sterilization technology and the raw materials with a general bacterial count of 10,000,000 / g or more and coliform bacteria of 1,000,000 / g or more. this Non-heated mill sterilization technology can sterilize up to the number of bacteria that comply with the Food Sanitation Law.

We accept sterilization from a minimum of 500 grams.

Refer to detail

Tetra type with string

Tetra type with string Zabuton (Japanese cushion) type

Zabuton (Japanese cushion) type

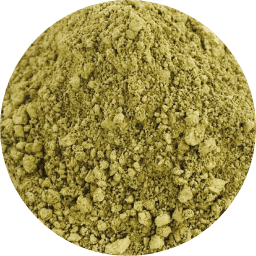

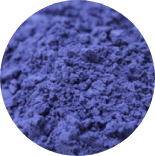

Butterfly pea

Butterfly pea Holy Basil

Holy Basil Hibiscus roselle

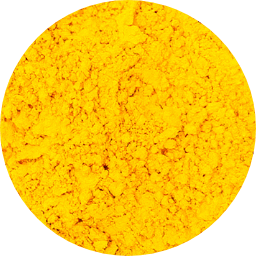

Hibiscus roselle Turmeric

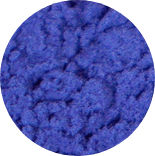

Turmeric Mulberry

Mulberry

Extract powder

Extract powder Powder /

Powder / Cut product

Cut product Dried product

Dried product Tea bags

Tea bags